Acoustical & vibration design retrofit Low-vibration & OSHA noise control

Novo Nordisk manufactures pharmaceutical products for diabetes care. The company’s significant R&D and manufacturing presence in the US includes the new Novo Nordisk Delivery Technology (NNDT) facility Hayward, CA. In establishing the facility in Silicon Valley, Novo chose to retrofit an existing 82,000ft2 building.

The retrofitted facility houses a drug delivery manufacturing line. One of the final steps requires a custom-built ballistic punch-press that generates large impact forces.

Sensitive receivers include a precision scale (50ft setback); a manufacturing tool with sensitive machine vision (116ft setback); and a laser-based micro-machining tool (176ft setback). In addition, the tool operators have workstations near the tool. Each of these, including the ballistic press, is located on a slab-on-grade floor.

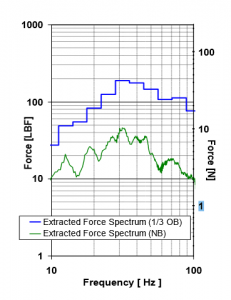

The Architect approached us during concept design to determine whether press operation might disturb sensitive receivers, even at long distances. We performed two types of tests: first, we performed testing to extract the dynamic forcing function of the prototype tool at the tool vendor’s facility; and secondly, we performed vibration propagation testing at the existing facility in Hayward.

The Architect approached us during concept design to determine whether press operation might disturb sensitive receivers, even at long distances. We performed two types of tests: first, we performed testing to extract the dynamic forcing function of the prototype tool at the tool vendor’s facility; and secondly, we performed vibration propagation testing at the existing facility in Hayward.

Using the dynamic force and the actual transfer functions from the retrofitted facility in Hayward, we were able to predict vibration response at the location of all vibrationsensitive receivers in the retrofitted facility, including human receivers working near the tool. The predictions were compared with tool criteria and OSHA guidelines.

We also addressed the noise impact of ballistic press operation. We designed absorptive panels in the walls and ceiling of the tool space to minimize noise levels both in the immediate vicinity as well as in adjacent spaces.