Noise, vibration and EMI measurement

Eli Lilly & Co. is a leading pharmaceutical research and manufacturing company, based in Indianapolis, Indiana. Lilly maintains research facilities at the corporate headquarters here, as well as at other locations in the US.

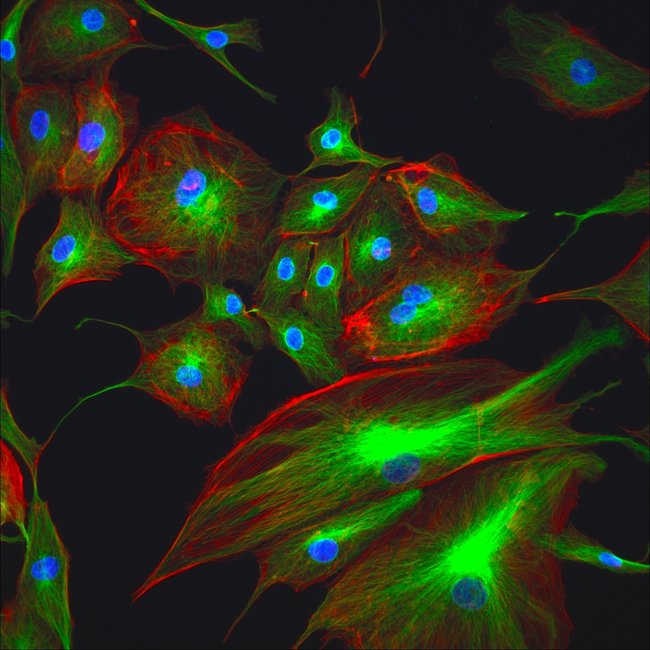

Physical Electronics (PHI) was contracted to provide three surface analysis tools for the Corporate Research Center in Indianapolis. These spectroscopy tools work in the Xray, Auger electron, and secondary-ion mass domains. Each tool is used to characterize surfaces for composition and other properties.

All three tools require demanding vibration, noise, and EMI environments due to the micro- and nanometer scale on which these tools operate.

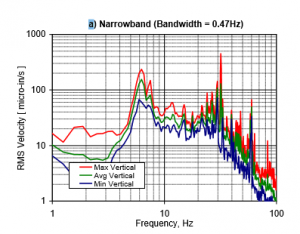

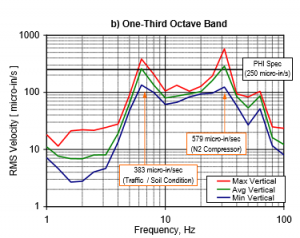

We performed comprehensive environmental surveys of the preferred tool installation locations. In these surveys, we quantified the existing ambient vibration, noise, and EMI. While the EMI and noise environments were found to be acceptable, the vibration environment failed to meet the PHI criterion.

The vibration failure occurred in two different frequency bands: 6.3Hz and 31.5Hz. Both failures were intermittent; vibration levels at these frequencies varied dramatically over time. We identified the exceedances during our visit, and were able to determine the vibration sources the same day

.

The 6.3Hz exceedance was found to be due to the passage of heavy trucks on nearby streets. The site soil condition resulted in efficient propagation of vibration around this frequency. The building foundation could be modified to mitigate this. Because traffic was outside of Lilly’s control, and because addressing the exceedance would require expensive modifications of the foundation, Lilly staff decided to accept occasional interruption of their work due to this vibration source. As a research lab, this infrequent interference was not expected to cause product losses, and the throughput losses were considered insignificant.

The exceedance in the 31.5Hz band was found to be caused by a nitrogen supply compressor that served the lab. The installation of a simple vibration isolation system was suggested to mitigate the impact of the compressor. Since this exceedance occurred many times per hour, the costs of mitigation became a reasonable investment.

a